It is unquestionable, that renewable and storage energy industry is growing dramatically during the past decades, therefore, in order to use renewable energy instead of traditional fossil resources, it is essential to deeply understand and working on improve battery’s performance, people realized by analyzing the result of GITT test, as Dee and etc.. Published in 2009, GITT experiments were conducted to determine the lithium diffusion coefficient of LiNi0.8Co0.15Al0.05O2, used as the active material in a lithium-ion battery porous composite positive electrode.

Thus, lots of customers were asking us if our software could achieve this test or not, and the answer is absolutely positive. . GITT uses time-domain voltage data resulting from a prescribed, low C-rate, long rest time, current discharge pulse train. (Shen, Z and etc.., 2013).

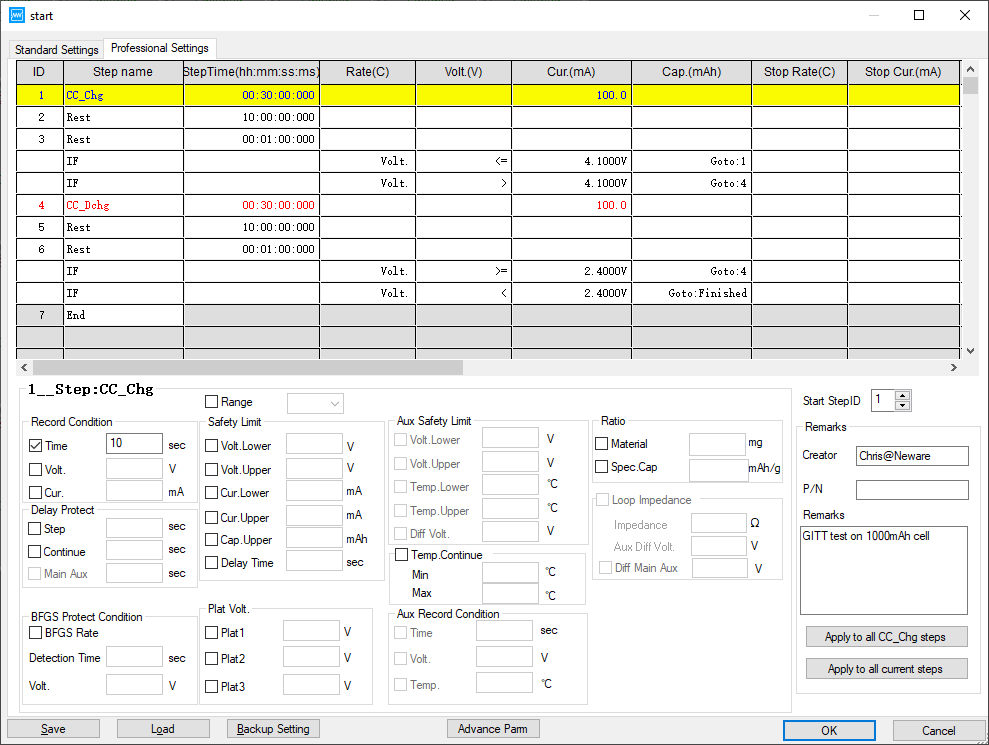

Now, I am going to show you how to do GITT test by using our software:

For your information, here, we are using our BTS4000-5V6A and Neware BTS7.6.0 to do the test. And you can download the GITT testing profile from here.

As you can see, the whole test process is easy to understand, and to be more specific, all working steps can only be divided into three catalogs, which is charge, discharge and rest respectively. *

Step 1. Chrage the cell. Use 0.1C current and CC mode(Constant current) to charge the cell up to 30 mins.

Step 2. Rest the cell for the longest time you could possibly wait, usually we’d suggest 10 hours. Because the longer time we wait, the more balance of Li+’s diffusion we could possibly get.

Here, we set up the resting period for 10 hours, which is completely longer enough.

After resting the battery, we set up the ‘if’ step, if the voltage is less than 4.2V, then the test procedure will automatically go back to step 1(contintue to charge the cell to be sure it can reach its highest voltage). If the cell voltage is higher or equal than 4.2V, test procedure till move on to the next step, step 3.

Step 3.Discharge the cell by using 0.1C current(Constant current mode) up to 30mins.

Step 4. Rest the cell for a long time, this is in order to test the speed of the Li+ when it back to the negative electrode. Now, put on the rest mode for up to 10 hours, same as step 2. And in this step, the ‘if’ step will be limited by the lowest voltage, if the voltage is higher than 2.4V, then go back to dischrage step to continue discharing the cell. If the cell voltage is lower or equal to 2.4V, then the whole test is finished.

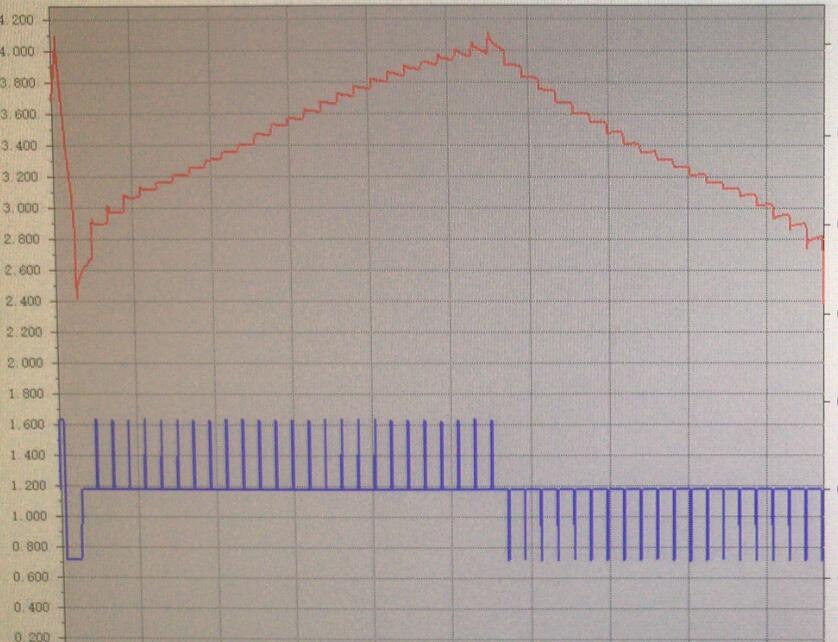

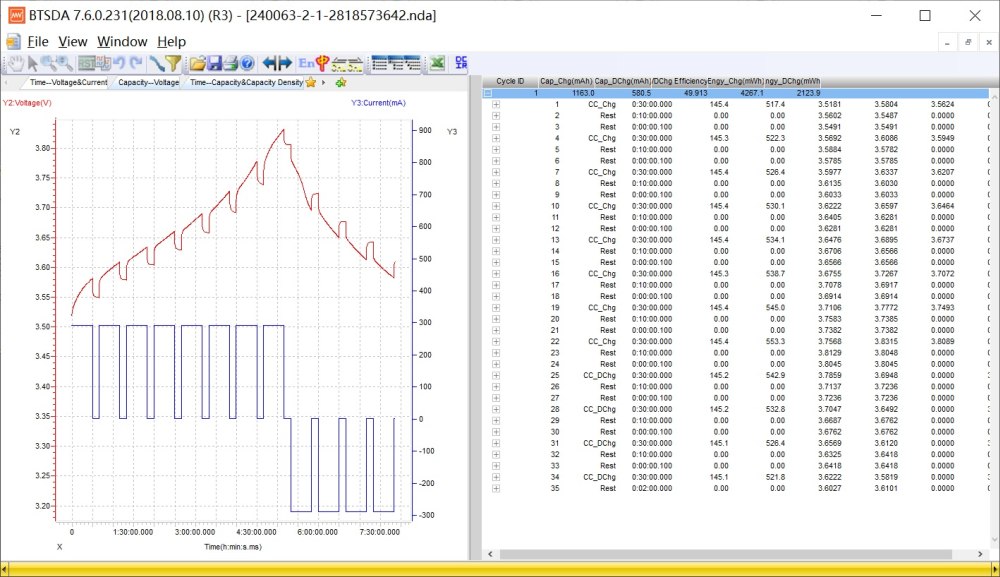

After the test, as we can see from the plot/graph below:

We’ve uploaded the NDA test result for your reference. You can download it from here: GITT test result on Neware BTS4000-5V6A.

Just want you to know that we’ve shortened the rest time to 10 mins, so the result is kind of different from the standard GITT test. When you perform the GITT test, please use the below profile(only change the current according to your cell parameters, don’t change the rest time).

You can also download the GITT test profile from here and load it directly to your BTS software for easier operation.

Reference List:

Dees, D. W., Kawauchi, S., Abraham, D. P., & Prakash, J. (April 01, 2009). Analysis of the Galvanostatic Intermittent Titration Technique (GITT) as applied to a lithium-ion porous electrode. Journal of Power Sources, 189, 1, 263-268.

Shen, Z., Cao, L., Rahn, C. D., & Wang, C.-Y. (January 01, 2013). Least Squares Galvanostatic Intermittent Titration Technique (LS-GITT) for Accurate Solid Phase Diffusivity Measurement. Journal of the Electrochemical Society, 160, 10.)

Comments are closed.